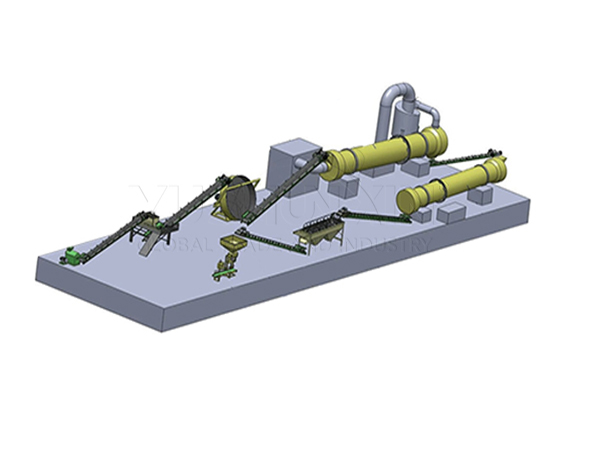

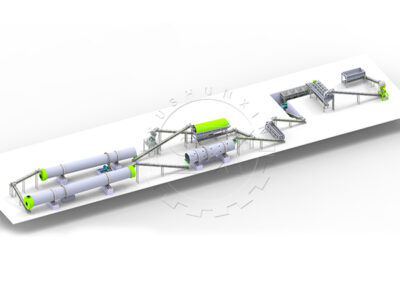

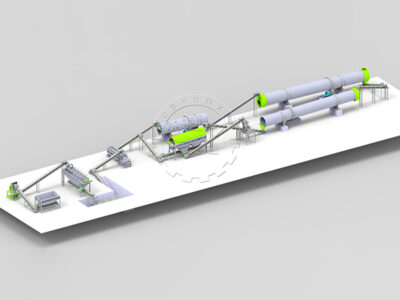

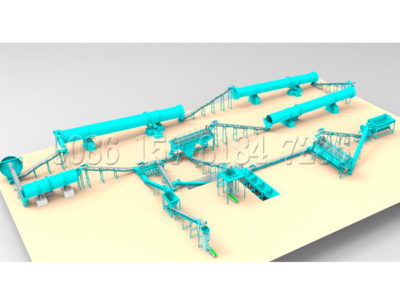

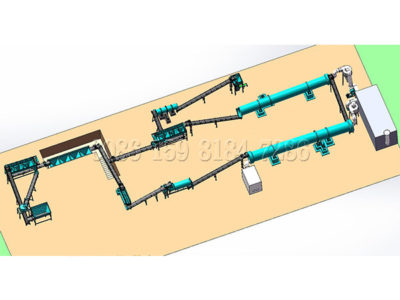

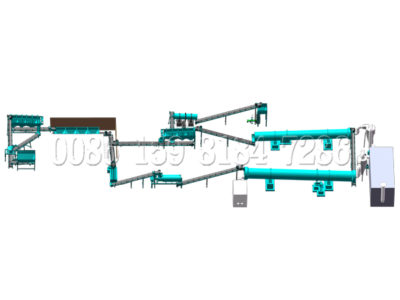

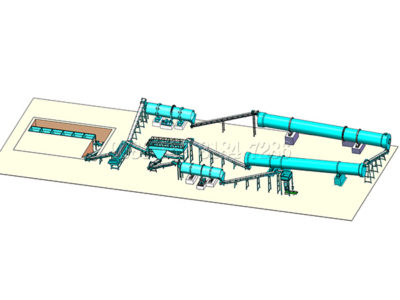

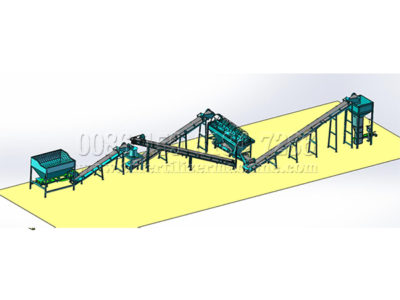

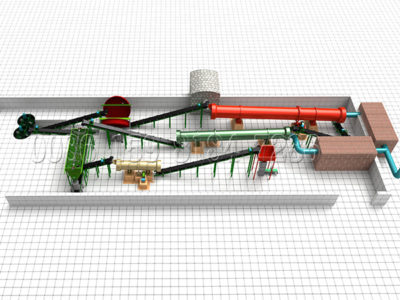

The cat litter production line refers to the complete process and set of equipment used to manufacture cat litter from raw materials to finished packaged products. It typically consists of several stages, including crushing, screening, mixing, granulating, drying, and cooling.

Working Process

1. Raw Material Handling: The production process starts with handling the raw materials. Common materials used for cat litter include clay (bentonite), silica gel, recycled paper, wood shavings, or other biodegradable substances. Raw materials need to be cleaned, dried, and screened to remove impurities and ensure consistency.

2.Mixing: Once prepared, the raw materials are mixed together according to a specific formula. The mixing process is crucial to achieve the desired characteristics of the cat litter, such as clumping ability, odor control, and absorption capacity. Additives like odor neutralizers or coloring agents may also be incorporated at this stage.

3.Granulating: The blended material is then processed through granulation equipment to form the cat litter particles into the desired size and shape. This step can involve extrusion, pelletizing, or other forming techniques depending on the type of cat litter being produced.

4. Drying: After granulating, the cat litter particles are dried to reduce moisture content. This helps improve product stability, prevent microbial growth, and ensure the litter maintains its desired properties during storage and use.

5. Packaging: Once dried, the cat litter is ready for packaging. Packaging can be done using automated systems that fill bags or boxes with the cat litter, and labels may be applied as per branding requirements.

6. Storage and Distribution: Finally, the packaged cat litter products are stored in warehouses and prepared for distribution to retailers or directly to consumers.

Features

1.Customization: This line is customizable according to different raw materials, production capacities, and product specifications.

2.Efficient Processing: Equipped with advanced machinery and technologies aimed at maximizing efficiency and productivity throughout the production process. This may include automated systems for material handling, mixing, granulation, drying, and packaging, reducing labor requirements and minimizing production downtime.

3.Quality Control: Quality control measures are implemented at various stages of the production process to ensure the consistency, purity, and safety of the final products.

4.Reliability and Maintenance: This line is engineered for reliability and durability, with robust construction and components designed to withstand the rigors of continuous operation.

5.Environmental Sustainability: Designed with environmental sustainability in mind, incorporating technologies and practices aimed at reducing energy consumption, minimizing emissions, and mitigating environmental impact.